MANUFACTURING CAPABILITIES

Over the past few decades, the company has gradually established a complete production line that integrates research and development, production, and processing, with precise and strict inspection and testing processes to ensure stable product performance and reliable quality.

Material Fabrication Technology

Inspection and Testing

R & D Capabilities

Material Preparation Technology

Powder metallurgy technology includes hot isostatic pressing, cold isostatic pressing, sintering, vacuum sintering, and molding techniques.

Melting technology includes vacuum induction melting, vacuum consumable melting, and electron beam melting.

Deformation technology includes techniques such as forging, rolling, and extrusion.

Spray technology includes plasma spraying and supersonic spraying technologies.

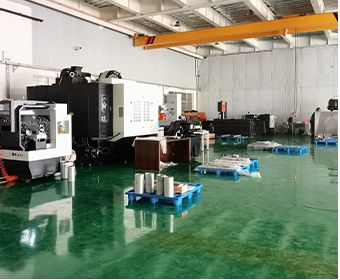

Machining Technology

Advanced Targets is a professional target material supplier in China, processing a wide variety of materials. We have a professional team and high-precision equipment to cope with a variety of material processing technologies in batches. We have complete lathes, milling machines, and grinding equipment to ensure a complete set of processing techniques for our products.

During years of experience in materials providing and manufacturing, Advanced Targets built a complete machining and producing line including below:

Powder Metallurgy

HIP

CIP

Sintering

Vacuum Stintering

Pressing

Deforming Technology

Forging

Rolling

Extrusion

Spraying

Plasma Spray

Ultrsonic Spraying

Machining

Lathing

Milling

Grinding

Bonding

Inspection and Testing

In order to inspect the quality of the targets, Advanced Targets cooperates with National Nonferrous Metal & Electronic Testing Center to inspect the impurity and microstructure of the targets for their uniformity.

Most of the inspection technologies we use are: ICP, LECO, SEM, Optical microscope and C-scan (Ultrasonic testing) technology.

Research and Development Capabilities

Hebei HongTarget Technology Co., Ltd. and the Institute of Process Engineering of the Chinese Academy of Sciences have established an industry university research cooperation to jointly commit to the research and development of new coating targets. The main research directions include: Development of targets for multi-element alloy thin film solar cells, Preparation of targets for ceramic high-temperature tool coating

At the same time, internal researchers of the company have been committed to the research and innovation of new materials for hard coatings on cutting tools and molds. Continuously experimenting with new elements and new process products

| Alloy | Composition |

| Cr base | CrMo, CrW, CrNiAISi |

| CrAl base | CrAISi, CrAIV, CrAIW, CrAIB, CrAlSiW, AITiCrSiY |

| TiAl base | TiAICr, TiAISi, TiAITa, TiAIW, TiAINb |

| Others | NiCrAlY, AlSnCu |

| The effect of TiAl based composite material addition on performance improvement: | |||

| +hardness | Ta | B | +hardness+grain ref |

| +low friction +hardness | V | Si | +hardness+Nano composite |

| +oxidation res.+ hardness | Zr | W | +low friction +wear res. |

| +corrosion res. | Cr | NB | |