Product.

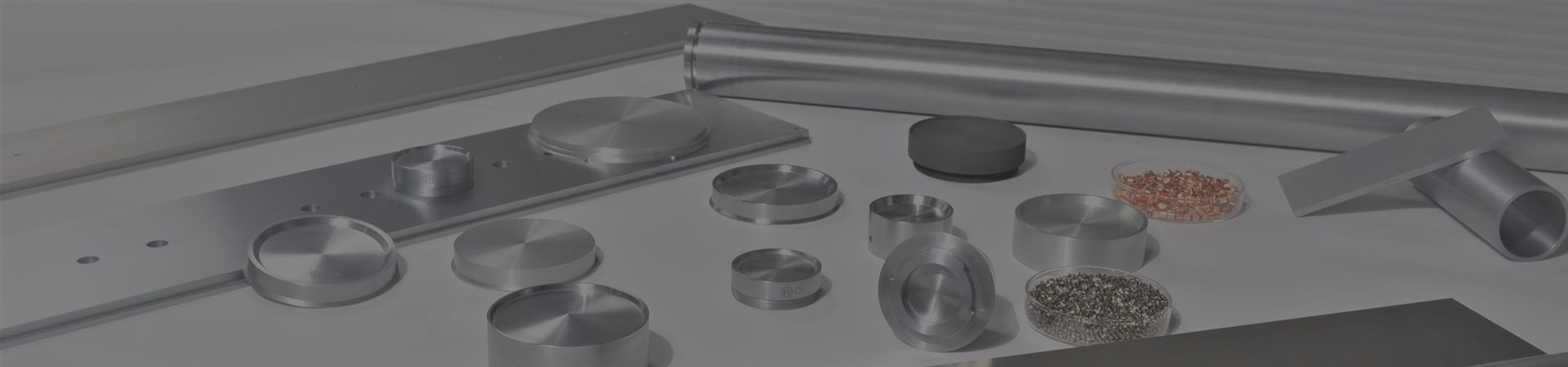

PVD Sputtering Targets

As a leading PVD sputtering targets supplier and manufacturer, Advanced Targets specializes in providing high-quality sputtering targets and cathodes that are essential for various industries relying on Physical Vapor Deposition (PVD) technology. Our PVD materials for thin films are engineered to meet the demanding requirements of semiconductor, solar energy, optical coatings, and other advanced applications.

What is a sputtering target?

The term "target material" in sputtering targets originates from the common target materials used in shooting. During the PVD coating process, the coating material is bombarded by electron beams or ion beams, similar to a target being shot, hence the name "target material." Sputtering is one of the main techniques for evaporation materials for thin films. It utilizes ions generated from an ion source, which are accelerated and gathered in a vacuum to form a high-speed ion beam. This ion beam strikes the surface of a solid and exchanges kinetic energy, causing particles from the solid surface to be ejected from the solid and deposited on the substrate surface.

Sputtering Target Properties

The high-purity sputtering targets governs the physical and mechanical properties of the sputtered film and affects the quality of the coating.

Low impurity content and high purity.

High density.

Uniform composition and organization.

Small grain size.

What are the uses of sputtering targets?

Sputtering targets are used for the production of thin film deposition materials typically metallic films or other compound films. These thin film deposition materials are utilized in a variety of applications:

For the manufacture of integrated circuits and other electronic components.

For the production of mirrors, lenses, and other optical components.

General coatings: to enhance the appearance of products and increase wear resistance, among other things.

For the fabrication of layers in solar cells.

For the production of magnetic thin films, such as those used in magnetic storage devices.

Why Choose Advanced Targets for Your PVD Sputtering Targets?

Material Purity and Quality Control

The purity of sputtering targets plays a pivotal role in the quality of the thin films deposited. We ensure our high-purity sputtering targets are manufactured to the highest industry standards, enabling you to achieve superior results in your thin film applications.

Cost-Efficiency

At Advanced Targets, we strike the balance between cost and quality. Our sputtering targets are designed to deliver high performance at competitive prices, ensuring you achieve cost-efficiency without compromising on quality.

Customization for Specific Applications

Every industry has unique requirements when it comes to sputtering targets, whether it's for semiconductor manufacturing, solar panels, or optical coatings. Our team works closely with clients to provide customized sputtering targets tailored to meet specific application needs. This allows for greater precision and optimal film quality.

On-Time Delivery

Timely delivery is essential for manufacturers who rely on PVD sputtering materials for their production lines. We prioritize on-time delivery and maintain a reliable supply chain, ensuring that you never experience costly downtime due to material shortages.

Global Reach with Local Support

Our clients range from semiconductor manufacturers in North America to solar energy innovators in Asia. No matter where you're located, our global reach combined with personalized customer support ensures you get the materials you need, when you need them.